Are there differences between them besides their packaging? Do they both have all the same features?

7,022 posts

·

Joined 2010

7,022 posts

·

Joined 2010

im not taking anything away from stinger and PIMP, obviously they buy their componets from DIYautotune... but, personally, i would rather get mine from the source. my $.02.

244 posts

·

Joined 2002

Please do not act as if you know about our product when it's clear you do not. This is the second time you've improperly answered questions about our product. The only thing "obvious" is that you don't know anything about our product but choose to act as if you do. You don't even know the relationship between MegaSquirt and MicroSquirt and rather than figuring it out, you state we must have a type on our website.

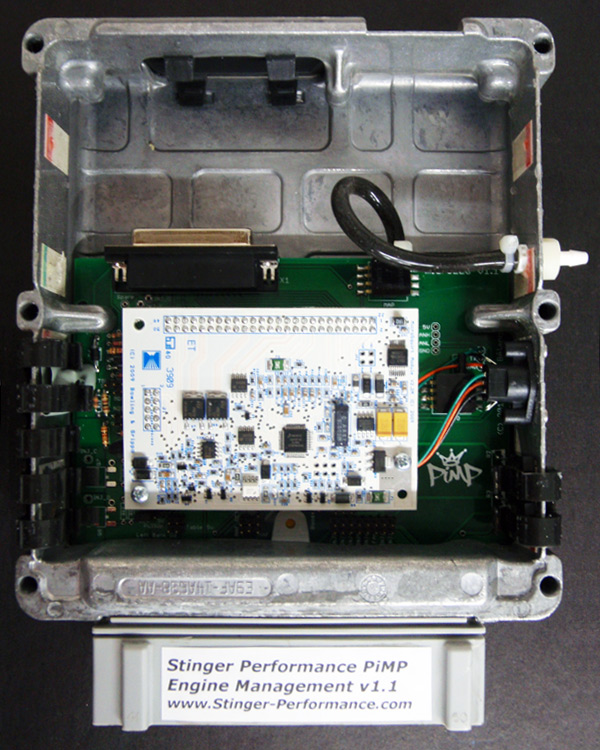

I'd just like to clarify that while the PiMP is MicroSquirt (MS2) based, it is most certainly not an "assembled DIY kit". We buy not a single component from DIY for our ECU's. We get the MicroSquirt modules directly from B&G (the white board) and the green board is custom made for use (our logo is on the board) and they are assembled with all surface mount components by Stinger Performance.

Not only are they all surface mount just like factory ecu's (unlike the DIY kits), they also have internal jumpers that can be plugged into different locations for different options without any soldering. This also allows the same ecu to work in nearly any 83-94 Ford without any soldering. Just move a few jumpers to swap it from a 2.3 to a 5.0 for example. Of course having this in the factory case also allows it to fit in the stock location in the stock hanger and plug into the factory harness.

Regarding the original post:

While they do share some features, we have additional features beyond what DIY offers (see the paragraph above for some of them).

It will control both high and low impedance injectors for 4 cylinders, or high impedance for v8's.

I'd just like to clarify that while the PiMP is MicroSquirt (MS2) based, it is most certainly not an "assembled DIY kit". We buy not a single component from DIY for our ECU's. We get the MicroSquirt modules directly from B&G (the white board) and the green board is custom made for use (our logo is on the board) and they are assembled with all surface mount components by Stinger Performance.

Not only are they all surface mount just like factory ecu's (unlike the DIY kits), they also have internal jumpers that can be plugged into different locations for different options without any soldering. This also allows the same ecu to work in nearly any 83-94 Ford without any soldering. Just move a few jumpers to swap it from a 2.3 to a 5.0 for example. Of course having this in the factory case also allows it to fit in the stock location in the stock hanger and plug into the factory harness.

Regarding the original post:

While they do share some features, we have additional features beyond what DIY offers (see the paragraph above for some of them).

It will control both high and low impedance injectors for 4 cylinders, or high impedance for v8's.

86five-o

Discussion starter

562 posts

·

Joined 2010

Stinger Performance Plug-in Microsquirt Powered (PiMP) engine control unit is the most user-friendly and capable plug and play option available for Ford EEC-IV equipped vehicles.

Not doubting you just trying to get as much information before I buy anything.

Not doubting you just trying to get as much information before I buy anything.

740 posts

·

Joined 2010

just wondering how you came to this conclusion? Not trying to argue. Just wondering if this is from your own experience or from their ad?

7,022 posts

·

Joined 2010

i saw where they mention micro in the first paragraph... the third paragraph says it based on megasquirt technology???????????

1,593 posts

·

Joined 2006

The MicroSquirt is a scaled down MS2 using the same code. I know Stinger uses a MicroSquirt Module but I'm not sure what features are on the board they mount it on.

412 posts

·

Joined 2005

I'm sure the PIMP is a great product, I've known the designer Wes Kiser for many years now and he's a great guy, super sharp, and we have alot of respect for one another. Assassin is correct they purchase the uS Modules through B&G directly and not through us so we don't see a dime from PIMP ECU sales.

To clear up the misinformation for thru-hole versus SMD, while it's true our DIYPNP units use through-hole components so the home assembler can solder them up easily-- the MSPNP Gen2's use surface mount components however. In reality that's more about mass-manufacturing and has a very small effect on durability, though there is some small benefit to SMD. We do it for that reason and also to maximize efficiency in manufacturing. It doesn't always cost less, but it's easier and consistent.

As for low versus high impedance injectors I'm not sure what the PIMP uses, (VND's I think?) though I can speak to the MSPNP Gen2 which uses true Peak-N-Hold circuitry to peak open the injectors at 4 amps, and hold them at 1 amp to prevent overheating the injectors. Peak-N-Hold capability also maximizes injector performance by minimizing injector opening/dead times as compared to some of the other methods we could have chosen to use.

We considered using VND's which we do use on some other products, but have found that while they work very well for high impedance injectors, and can in some limited cases work with low-z injectors, they don't work well for low impedance injectors in many cases. The problem is that they max out at 5amps and current limit which causes heat to be generated, a little heat can be dissipated through a well designed heatsink- but many low-z injectors will generate a LOT of heat in this circuit and can cause problems. Based on ohm's law (google an ohm's law calculator, it's easy to do this math) they 'should' work fine for an injector that's 2.7 ohms or higher assuming 13.2v in the charging system. Anything under 2.7 ohms will try to drive the transistor harder than 5amps which will current limit the transistor and begin to generate heat, and if they get hot enough they will not function properly, usually after the car is nice and warm and you're in the middle of a dyno session or race and seem to have an 'intermittent problem' that doesn't occur when the car is cold, which makes sense as it takes a few minutes to overheat the VNDs and start causing the problem.

We had this happen recently on a customer's Miata that was using a DIYPNP (which uses VND's) and prepping for the SOLO Nationals, they were having problems when tuning that was causing the injectors to drop out, they thought it was an ignition problem, but when we heard what injectors they were using we determined they were simply using the wrong ECU for the injectors they had. (They could have used a resistor pack or external PnH box to solve the problem). As time was tight, we got them setup with an MSPNP Gen2 for their car and the internal PnH circuit immediately solved their problem.

The MSPNP Gen2 also has a very slick analog knock control circuit that's tunable. It's not as slick as the digital knock circuit we've got available for MS3 now, but it works in much the same way just using analog circuitry to do so giving you the noise floor and knock frequency tuning without the windowing capability MS3 has. It also has a headphone jack allowing you to listen to the knock sensor when tuning using it as a set of detcans, which can be helpful when tuning. (knock sounds like a scratching or static-like noise when listening with detcans like this).

To clear up the misinformation for thru-hole versus SMD, while it's true our DIYPNP units use through-hole components so the home assembler can solder them up easily-- the MSPNP Gen2's use surface mount components however. In reality that's more about mass-manufacturing and has a very small effect on durability, though there is some small benefit to SMD. We do it for that reason and also to maximize efficiency in manufacturing. It doesn't always cost less, but it's easier and consistent.

As for low versus high impedance injectors I'm not sure what the PIMP uses, (VND's I think?) though I can speak to the MSPNP Gen2 which uses true Peak-N-Hold circuitry to peak open the injectors at 4 amps, and hold them at 1 amp to prevent overheating the injectors. Peak-N-Hold capability also maximizes injector performance by minimizing injector opening/dead times as compared to some of the other methods we could have chosen to use.

We considered using VND's which we do use on some other products, but have found that while they work very well for high impedance injectors, and can in some limited cases work with low-z injectors, they don't work well for low impedance injectors in many cases. The problem is that they max out at 5amps and current limit which causes heat to be generated, a little heat can be dissipated through a well designed heatsink- but many low-z injectors will generate a LOT of heat in this circuit and can cause problems. Based on ohm's law (google an ohm's law calculator, it's easy to do this math) they 'should' work fine for an injector that's 2.7 ohms or higher assuming 13.2v in the charging system. Anything under 2.7 ohms will try to drive the transistor harder than 5amps which will current limit the transistor and begin to generate heat, and if they get hot enough they will not function properly, usually after the car is nice and warm and you're in the middle of a dyno session or race and seem to have an 'intermittent problem' that doesn't occur when the car is cold, which makes sense as it takes a few minutes to overheat the VNDs and start causing the problem.

We had this happen recently on a customer's Miata that was using a DIYPNP (which uses VND's) and prepping for the SOLO Nationals, they were having problems when tuning that was causing the injectors to drop out, they thought it was an ignition problem, but when we heard what injectors they were using we determined they were simply using the wrong ECU for the injectors they had. (They could have used a resistor pack or external PnH box to solve the problem). As time was tight, we got them setup with an MSPNP Gen2 for their car and the internal PnH circuit immediately solved their problem.

The MSPNP Gen2 also has a very slick analog knock control circuit that's tunable. It's not as slick as the digital knock circuit we've got available for MS3 now, but it works in much the same way just using analog circuitry to do so giving you the noise floor and knock frequency tuning without the windowing capability MS3 has. It also has a headphone jack allowing you to listen to the knock sensor when tuning using it as a set of detcans, which can be helpful when tuning. (knock sounds like a scratching or static-like noise when listening with detcans like this).

1 post

·

Joined 2012

In general there is much confusion among those that aren't all super MS geeky as to what constitutes a megasquirt (this literally now means dozens of potential products).

In our advertising for the PiMP, when we say this is not an "assembled DIY kit," we mean specifically it is not a traditional MS2.2/3.0 board assembled by anyone, specifically in a custom fashion. It is not meant as a specific dig on the company DIY Autotune, which is a great company that has done much for the MS community. All of these units are to some extent "snowflakes," specifically built and customized for particular applications, and function/reliability frequently depended on how the assembler handled these interface customizations.

The PiMP board is a custom interface board for the microsquirt module (basically a surface mount assembled baby MS2), that support EEC IV applications very well in a PNP fashion. It fits in the factory location, and is capable of controlling 2.3t, 2.3, and 5.0 applications with no additional assembly on the part of the end user, with no modifications to switch between these applications (beyond configuring hardware jumpers). We only sell these units completely assembled, and they are a mix of SMT and through hold components. The only "off board" wire on the entire unit is for the communication interface.

DIY's MSPNP and MSPNP Gen2 units are also not traditional megasquirts. As "Foundsoul" pointed out, the Gen 2 units have a similar feature set to the PiMP, as well as 4 peak and hold injector drivers and a knock conditioning circuit. Our PiMP supports 4 cylinder low-z injectors, but does so via a small internal resistance. In practice we have had no issues obtaining acceptable performance with 95 lb low-z injectors, but we are not using a true peak and hold driver.

Which unit is better for you truly depends on your goals. What are your goals/needs, and for what application? By this I don't mean performance goals. More critical to answer this question is what ignition system, what features do you want to use, where do you want to mount it, sequential or batch, etc.....

In our advertising for the PiMP, when we say this is not an "assembled DIY kit," we mean specifically it is not a traditional MS2.2/3.0 board assembled by anyone, specifically in a custom fashion. It is not meant as a specific dig on the company DIY Autotune, which is a great company that has done much for the MS community. All of these units are to some extent "snowflakes," specifically built and customized for particular applications, and function/reliability frequently depended on how the assembler handled these interface customizations.

The PiMP board is a custom interface board for the microsquirt module (basically a surface mount assembled baby MS2), that support EEC IV applications very well in a PNP fashion. It fits in the factory location, and is capable of controlling 2.3t, 2.3, and 5.0 applications with no additional assembly on the part of the end user, with no modifications to switch between these applications (beyond configuring hardware jumpers). We only sell these units completely assembled, and they are a mix of SMT and through hold components. The only "off board" wire on the entire unit is for the communication interface.

DIY's MSPNP and MSPNP Gen2 units are also not traditional megasquirts. As "Foundsoul" pointed out, the Gen 2 units have a similar feature set to the PiMP, as well as 4 peak and hold injector drivers and a knock conditioning circuit. Our PiMP supports 4 cylinder low-z injectors, but does so via a small internal resistance. In practice we have had no issues obtaining acceptable performance with 95 lb low-z injectors, but we are not using a true peak and hold driver.

Which unit is better for you truly depends on your goals. What are your goals/needs, and for what application? By this I don't mean performance goals. More critical to answer this question is what ignition system, what features do you want to use, where do you want to mount it, sequential or batch, etc.....

147 posts

·

Joined 2004

I can say if you're on the Stinger forum, it never takes 2 months to get an answer, not even 2 days.

Not knocking DIY and Megasquirt but I'm gonna say for anyone looking to buy a PiMP unit, if you join the forum and message/email Assassin (not his name on his forum) then you will surely be answered in a very timely fashion and your product purchase will be fully supported. The argument about PiMP questions not being answered here to suite you by speed is like posting here about an Apple product and then getting ticked cause Tim Cook doesn't come here within 3 hours and answer you. They have their own forum for their product questions, so does Stinger.

Not knocking DIY and Megasquirt but I'm gonna say for anyone looking to buy a PiMP unit, if you join the forum and message/email Assassin (not his name on his forum) then you will surely be answered in a very timely fashion and your product purchase will be fully supported. The argument about PiMP questions not being answered here to suite you by speed is like posting here about an Apple product and then getting ticked cause Tim Cook doesn't come here within 3 hours and answer you. They have their own forum for their product questions, so does Stinger.

7,022 posts

·

Joined 2010

147 posts

·

Joined 2004

Because I wanted to put my 2 cents into the mix and because the thread wasn't closed. I wasn't trying to reopen anything, my lack of response by 3 months should be proof of that.

I've got a MS system and it's been nothing but trouble, won't control the IAC and a few other issues but that's for another thread. I just thought it was crappy to jump Shawn because he didn't respond on this forum and didn't seem to respond fast enough on his own, they do have a phone number I believe. But it's all good dude... I'm glad you got your combo worked out... maybe another 2 years of piddling with my MS and I might have it working correctly (maybe).

I've got a MS system and it's been nothing but trouble, won't control the IAC and a few other issues but that's for another thread. I just thought it was crappy to jump Shawn because he didn't respond on this forum and didn't seem to respond fast enough on his own, they do have a phone number I believe. But it's all good dude... I'm glad you got your combo worked out... maybe another 2 years of piddling with my MS and I might have it working correctly (maybe).

4,654 posts

·

Joined 2002

Be happy to help. Fire off that thread and let us know the skinny.I've got a MS system and it's been nothing but trouble, won't control the IAC and a few other issues but that's for another thread.

147 posts

·

Joined 2004

Well at the moment, I took the system off the car it was installed on, so I can't test it any further at the moment. I'm trying to put together another car that I intended to put a MS system on OR was thinking about the pimp system, seems I've inherited the MS2 system.

I believe that whatever parts (transistors, etc.) control the IAC circuit are bad, that's my belief.

I believe that whatever parts (transistors, etc.) control the IAC circuit are bad, that's my belief.

4,654 posts

·

Joined 2002

Roger that. Well if you set up to use it again and have issues feel free to post up! I know I had some trouble with the IAC too but eventually I got it figured out.

2,220 posts

·

Joined 2006

If i were to do things all over again, i would use the PIMP computer. I didnt know about their stuff till after i bought the MS2 PNP kit. Not that there is anything wrong with the DIY autotune kit, but the PIMP kit looks much more complete, and it looks like they have done their homework with creating base tunes. It is just a much nicer package. It is also cheaper than DIY autotunes stuff now that they dropped the old $650 dollar kit, and now the mustang plug and play stuff is over 800.

I was also told by someone at DIY that i could add nitrous control to my MS2 board down the line, and when i called to try and get it done, they informed me that there was no good way to add nitrous control to the MS2 board and i would be better off just buying MS3 if i was going that route. Seems like everytime i talked to them on the phone, i got a different answer.

I was also told by someone at DIY that i could add nitrous control to my MS2 board down the line, and when i called to try and get it done, they informed me that there was no good way to add nitrous control to the MS2 board and i would be better off just buying MS3 if i was going that route. Seems like everytime i talked to them on the phone, i got a different answer.

4,654 posts

·

Joined 2002

They didn't drop it.now that [diyautotune] dropped the old $650 dollar kit, and now the mustang plug and play stuff is over 800.

87 - 93

MegaSquirt-II V3.57 plug and play for 1986-1993 5.0 Mustang DIYAutoTune.com

94 - 95

MegaSquirt-II V3.57 plug and play for 1994-1995 5.0 Mustang DIYAutoTune.com

$611 for either version.

140 posts

·

Joined 2013

As far as tech support goes, we will try our best to answer any MS related question. Keep in mind we cant answer specifics about other pnp's or units built by other parties. However, general diagnostic questions will be doable.

It should take no time to solve any and every problem. Dont get frustrated, This only leads to mistakes and thus worsens the mood. Its a project that must always be spearheaded with a sense of open mindedness. Sure, sometimes you get frustrated. But step back, breathe and relax. Its easier than you think.

May be easier then cooking.

We dont simply drop units. Just because its an older model of a unit, does not mean that it will be scrapped and sold off. There will always be a market for every product. One would think that MS1's are no longer sold, but they sell really well even today.

It should take no time to solve any and every problem. Dont get frustrated, This only leads to mistakes and thus worsens the mood. Its a project that must always be spearheaded with a sense of open mindedness. Sure, sometimes you get frustrated. But step back, breathe and relax. Its easier than you think.

May be easier then cooking.

We dont simply drop units. Just because its an older model of a unit, does not mean that it will be scrapped and sold off. There will always be a market for every product. One would think that MS1's are no longer sold, but they sell really well even today.

93 posts

·

Joined 2009

Thanks Jerry for not dropping the ms1 as i bought 2 last month and the support has been incredible from DYIAUTOTUNE and this forums members.As far as tech support goes, we will try our best to answer any MS related question.

We dont simply drop units. Just because its an older model of a unit, does not mean that it will be scrapped and sold off. There will always be a market for every product. One would think that MS1's are no longer sold, but they sell really well even today.

i might buy 2 more MS1s next month also.

412 posts

·

Joined 2005

As the guys above said, let us know when you're ready to work the IAC tuning issue out and we'll get on it with you, it shouldn't be a problem to work out.

Also I noticed the callout about the price of the MSPNP Gen2 being a bit more-- that's true. The MS2357 with PNP harness adapter is a bit cheaper and still available, which the guys above pointed out. We also have no less than three employees(and/or myself the owner) offering tech support daily on these and many other forums.... we're here to help if you need it!

Also I noticed the callout about the price of the MSPNP Gen2 being a bit more-- that's true. The MS2357 with PNP harness adapter is a bit cheaper and still available, which the guys above pointed out. We also have no less than three employees(and/or myself the owner) offering tech support daily on these and many other forums.... we're here to help if you need it!

838 posts

·

Joined 2012

I don't see why it wouldn't run an 86. Think of it this way, people use the MegaSquirt tuning system to tune all kinds of cars. The PiMP vs the PNP is a matter of packaging essentially. I can't say which is "better". I think more people here have run the PNP just because it's better known in this circle. I have a PiMP and like it just fine so far.

659 posts

·

Joined 2003

I have the PiMP in my 86 5.0 Capri and it's amazing. The OP ended up going PiMP for his 86 GT as well. Super easy to get going and their tech support is awesome. As mentioned above, the PiMP will run 83-94 eec4 cars w/o issue. 2.3's 2.3t's and 5.0's.

7,022 posts

·

Joined 2010

boy, oh boy... talking about eating a slice of humble pie... i ate the whole thing! after doing a little more investigating of the Stinger PiMP system, i decided to give it a try when i was in the market for a standalone again, and i have to say, so far im VERY impressed. i have actually apologized to Shannon for my passive-aggressive responses in this thread and he was gracious enough to not only accept it, but he sold me a PiMP and has been nothing but helpful since... ive said it before that i was very satisfied with my MS2PNP, i foresee that i will be very happy with the PiMP as well.

5,863 posts

·

Joined 2001

Why the switch from the pnp to the pimp?

I like them both and chose the MSPNP2. I thinks its a matter of splitting hairs. I liked the inj driver method gor the pnp a little better and the pimp required some work to work on a 94-95 gt.

I like them both and chose the MSPNP2. I thinks its a matter of splitting hairs. I liked the inj driver method gor the pnp a little better and the pimp required some work to work on a 94-95 gt.

3,585 posts

·

Joined 1999

The PiMP is pretty much the same as my unit, DIYPNPF60. Both use the same Microsquirt Module.

![Image]()

![Image]()

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 9.8M

- members

- 208K

- Since

- 2001

A forum community dedicated to Ford Mustang owners and enthusiasts. Come join the discussion about performance, production numbers, VIN decoders, modifications, troubleshooting, power adders, DIY tutorials, and more!