What is the best way to route new fuel lines? Any diagram or underside pictures? THANKS

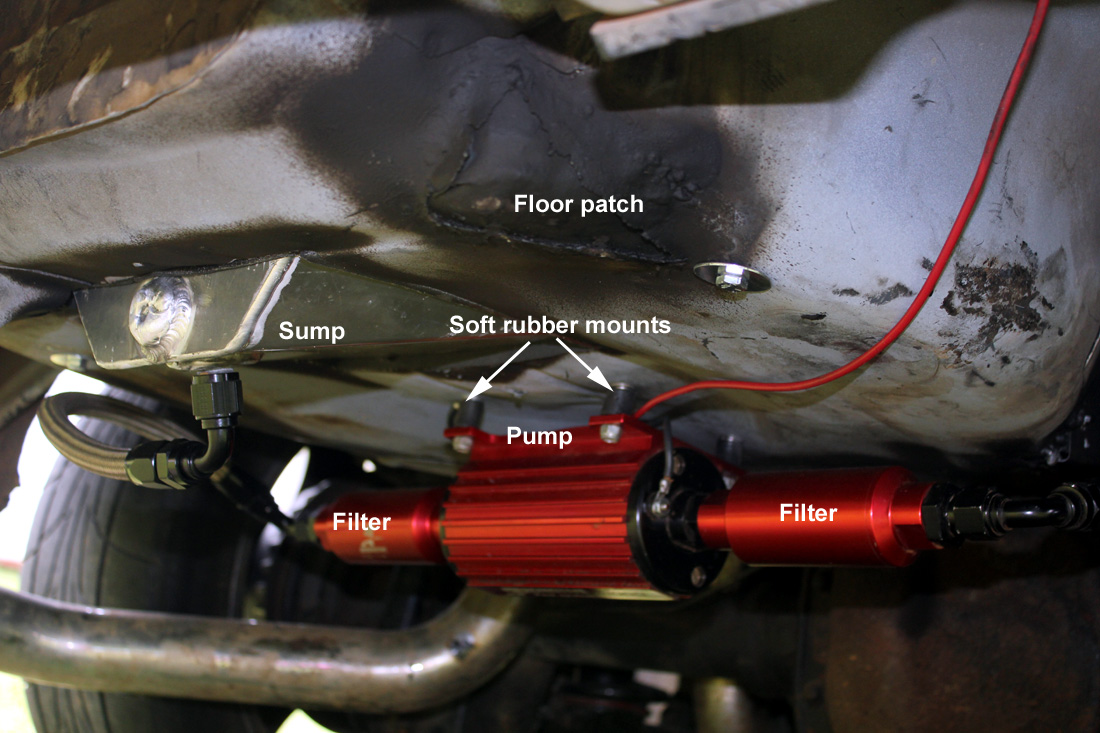

details: I'm using the stock tank with the UPR pickup, A1000 pump, 8 an braided to engine, 6 an return. Car has an 0n3 turbo, so exhaust only on passenger side near engine (then a y pipe and dual exhuast) - thinking I might run fuel under drivers side to keep it farther away from exhaust?

details: I'm using the stock tank with the UPR pickup, A1000 pump, 8 an braided to engine, 6 an return. Car has an 0n3 turbo, so exhaust only on passenger side near engine (then a y pipe and dual exhuast) - thinking I might run fuel under drivers side to keep it farther away from exhaust?